Sectors

Cardboard Production

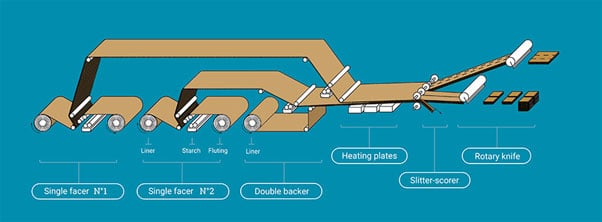

DMS have built up a wealth of experience monitoring machines in this industry over the years. Once the paper has arrived at the plant in rolls, they are loaded into a machine known as a corrugator. This machine is enormous in size, usually around 300 feet in length. Once inside the corrugator, the rolls of paper are heated, glued and then compressed together, creating corrugated cardboard.

Cardboard Production Process

First, the basics, a cardboard box is basically made up of a flute (made up of recycled paper), sandwiched between two liners. It is now very common for these liners to also be made up of a considerable proportion of recycled content, sourced from old cardboard or other sources of second-hand paper.

A corrugator is a complex machine that can vary in size and width, and generally can run at various line speeds, depending on the type of cardboard being manufactured. Due to the operating speeds of these machines the majority of components and assets on a corrugator are behind guards for safety reasons.

Obviously, this makes the monitoring of these critical components difficult and as the guarding of these types of machines increases year on year. This has

Monitoring Services

DMS have built up a wealth of experience monitoring these types of machines over the years, specialising not just on corrugating but also on conversion and the external services:

- Flute vacuum pumps

- Baler unit

- Baler fan

- Baler hydraulic pumps

- Dust extract fans

- Single facer main drive

- Single facer blowers

- Heat recovery pumps

- Linear splicer reels

- Double backer main drive

- Glue doctor roll bearings

- Pre-conditioning unit

- Accelerator and dancer rolls

- Dry end knifes

- Upper & lower stacker units

- Print units

- Former plates

- Vacuum fans

- Folder drives

- Impression cylinders

Equipment Manufacturers

We have worked on most original equipment manufacturers, to name but a few:-

- Mitisubishi

- BHS

- Fosber

- Ward

- Emba

- Gopfert

- Bobst

During our years of working with paper mills, we have provided the following services:-

- Vibration analysis / ultrasound regular routine surveys

- Electrical control panel thermal imaging surveys

- Gearbox inspections, removing inspections and using boroscopes

- Root cause analysis reports

- Installation of fixed monitoring systems on corrugator

- Lubrication services on regular weekly visits on the corrugator

- Ongoing fixed system remote asset monitoring