Sectors

Power Generation

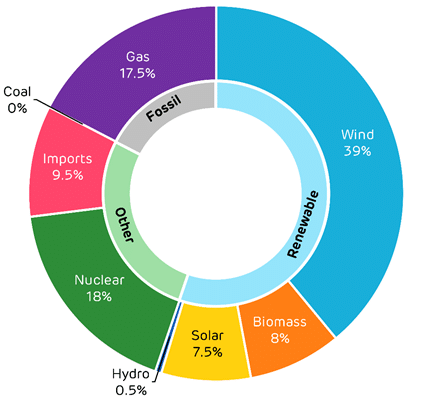

Electricity generation is decarbonising faster in Britain than anywhere else in the world. Changes to the way we produce power over the last six years have reduced carbon emissions by 100 million tonnes per year. The carbon savings made in Britain’s power sector are equivalent to having taken every single car and van off our roads.

Advanced Fixed Systems

This puts Britain at the forefront of the wider trend towards clean electricity. Coal generation is collapsing in Germany, having fallen 20% in the last year due to rising carbon prices. Renewables have beaten fossil fuels as the largest source of generation in Europe. A third of America’s coal power stations have retired over the last decade as they switch to cleaner natural gas.

DMS have seen first hand the change in the way power is generated in the UK over the last 10 years. We have been working closer and closer with the power generation sector as well as with the supporting infrastructures (ports, rail, etc) over this period. The change is dramatic in the way power is generated, but also in the equipment that is now used to produce these new types of power generation.

As we have worked closer in the gas and biomass energy sectors, we have started to build a really strong offering that enables us to deliver products and services that are focused on the unique applications in these fields.

Our advanced fixed systems have been delivering a true machine health indicator on gas engine generator sets monitoring, all different types of techniques, such as;

- Vibration and temperature

- Oil condition and temperature

- Electrical signature analysis

- Displacement probes

Power Generation Services

In the conventional areas of power generation, we are used to providing various services and products into the power station. These services range from the following:-

- Lubrication – oil changes on turbines, control oil systems, oil inspections, level checks, grease inspections, grease tasks, etc.

- Oil sampling – turbine oil, conventional asset sampling, etc.

- Vibration analysis – undertaken on all assets

- Thermal imaging – undertaken on gas turbines, electrical control panels, etc.

- Ultrasound – used to support vibration on rotating assets, compressed air leaks, vacuum leaks, steam traps, etc.

- Laser alignment – pump assemblies, fans, etc.

- Gearbox inspections – cooling tower gearboxes, etc.

Types of Assets Monitored

As you can imagine we used to working on all types of assets within the power generation sector, such as;

- Boiler feed pumps

- Cooling towers

- Flue Gas Condensing fans

- Induced Draft Fans

- Turbines

- Air fans (primary and secondary)

- Vacuum pumps

- Treated water pumps

- Wood chippers

- Disc screens

- Ash screws

- Chain conveyors

- Belts conveyors

- Gas engine generator sets