Services | Engineering Studies & Analysis

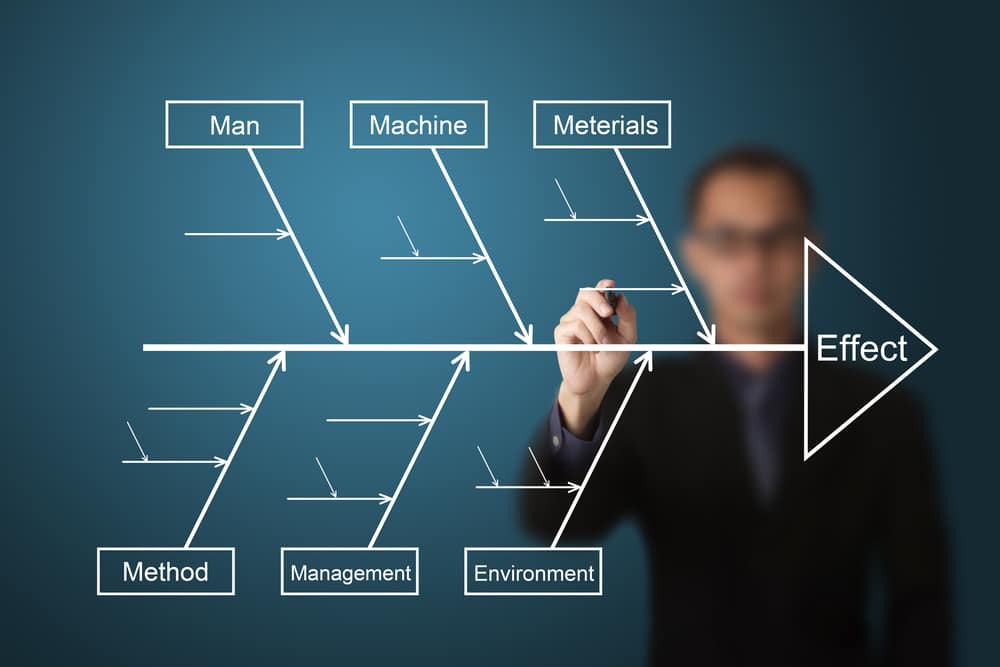

Root Cause Analysis Studies

Complete Data Analysis

We will use our existing equipment (both condition-based monitoring and visual inspection types) to take a series of readings / images to delve deeper into the cause of the issue.

Once we have gathered all the information and spoke extensively with the operations and engineering team on site, we are able to accumulate a lot of data that can be analysed to enable us to produce a thorough and comprehensive report.

Over the years we have been involved in various projects, and some are listed below;

- Crushing / Rolling Mill catastrophic failures

- Cereal plant flaking mill failures

- Energy consumption costs based on a change in lubrication manufacturer and type

- Cardboard conversion plant printers, servo drive failures

- Quarry crusher mill main drive failure

- Mineral processing ball mill girth wheel issues / damage

- Pharmaceutical plant air handling fan unit failures and external damage

- Power Generation gas turbine vacuum leak issues & identification

- Food processing drive shaft failures

- Food processing ferrous / non-ferrous debris production line detection

- Centrifugal Crushing Mill bearing assembly support structure failure

- Quarry classifier bearing failures