Services | Lubrication Services

Hydraulic System Inspections

Hydraulic Service Packages

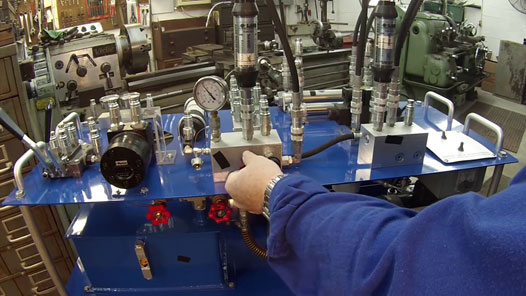

DMS can provide a complete service package for hydraulic systems, that includes:

- Oil sampling

- Breather inspections and changes

- Tank inspections, both visually and using video boroscopes

- Cleaning of the tank using lint free cloths

- Accumulator inspections, replacement and testing

- Hose supply and replacement

As with any industrial asset, there comes a time when it is not economical to repair and overhaul these assets. At this point DMS are able to supply an engineering design facility to specify and replace this system with a new modern-day system.

As part of this service, we can remove and install the new hydraulic system, ensuring the system is removed in line with your requirements.

Generally, the most important part of a critical hydraulic system, is the oil condition and cleanliness. Fluid cleanliness is of primary importance to hydraulic systems because the risks associated with contaminants can vary from parts malfunction, wear and tear in components, and longer response times of your system’s key parts.

DMS recognize the importance of fluid cleanliness and regularly assist clients by providing a mobile oil cleaning service. This service uses our own designed oil cleaning pump, which has 3 types of filters fitted, depending on what ISO cleanliness code the client requires, or what ISO cleanliness code we recommend.

As part of this service DMS take an oil sample prior to the cleaning process and again on completion to confirm the oil cleanliness.