Machine Monitoring

DMS Ltd develop and produce service based products and systems that identify, offer detailed information and monitor each individual assets performance. This detailed information enables our team of highly skilled employees to work in close partnership with the client and to identify areas for plant improvement. These improvements can vary greatly from small basic specification recommendations, to large scale planned engineering studies.

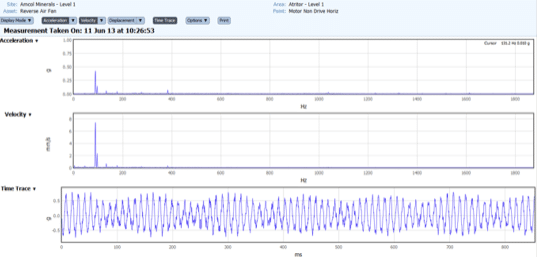

Frequency of vibrations are measured in detail to determine if the vibrations are indicating equipment deterioration or an impending defect. DMS use FFT (Fast Fourier Transformation) analysis software to determine defect frequencies for all applications.

Machine Sentry

Hand Held Vibration Analysers

DMS can supply and support the Machine Sentry (Blue Tooth) vibration analyser.

The Machine Sentry is a cost effective and efficient condition based monitoring tool that uses a unique web based interface, enabling remote diagnostics support.

Machine Sentry’s Vibration Analysis hardware and software runs on off-the shelf PDA’s and via the internet; making it the most versatile and cost-effective solution on the market.

Sub-Title

- Alert traffic lights on trends, spectra, time trace signal, etc.

- Vibration monitoring: ISO overall vibration limits (ISO 10816 etc)

- Velocity spectra

- Displacement spectra

- Acceleration overall spectra

- Acceleration peak-to-peak spectra

- Raw wave form signal

- Trending information on all measurements

- Ability to access detail information such as crest factor, peaks, etc.

Machine Sentry

Hand Held Vibration Analysers

DMS can supply and support the Machine Sentry (Blue Tooth) vibration analyser.

The Machine Sentry is a cost effective and efficient condition based monitoring tool that uses a unique web based interface, enabling remote diagnostics support.

Machine Sentry’s Vibration Analysis hardware and software runs on off-the shelf PDA’s and via the internet; making it the most versatile and cost-effective solution on the market.

Machine Monitoring

DMS Ltd develop and produce service based products and systems that identify, offer detailed information and monitor each individual assets performance. This detailed information enables our team of highly skilled employees to work in close partnership with the client and to identify areas for plant improvement. These improvements can vary greatly from small basic specification recommendations, to large scale planned engineering studies.

You can drag-and-drop it like any other Beaver Builder module. Then add all your questions with respective answers. That’s it! You can then customize the FAQ section with design settings.

In a module, you will find an option to enable schema support. Once you enable this option, FAQ schema will be automatically added to your page. In case you are using an external plugin to add schema you can keep it disabled.

The module follows Google guidelines and adds FAQ schema.